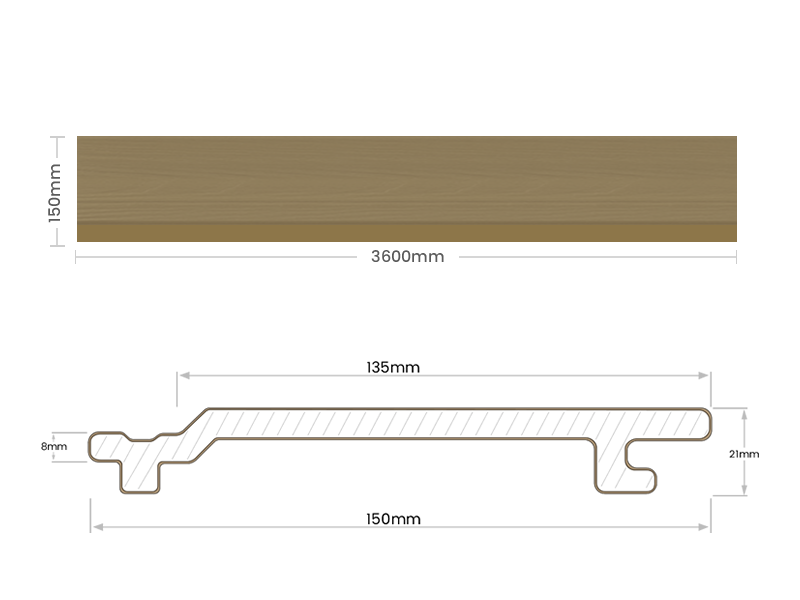

Composite cladding comes with lots of advantages that makes it a true alternative to wood.

- Superior durability than timber cladding.

- Lightweight – making it easy to install.

- Easy Maintenance – no need to stain, oil or paint, just a simple clean.

- Will not splinter, warp, swell or rot.

- Environmentally friendly.